January 2017

Heavy Metal

17/01/17 22:24 Filed in: Information

I'm not normally a fan of the "un-boxing" photo or video genre; however, I'll make an exception in this case!

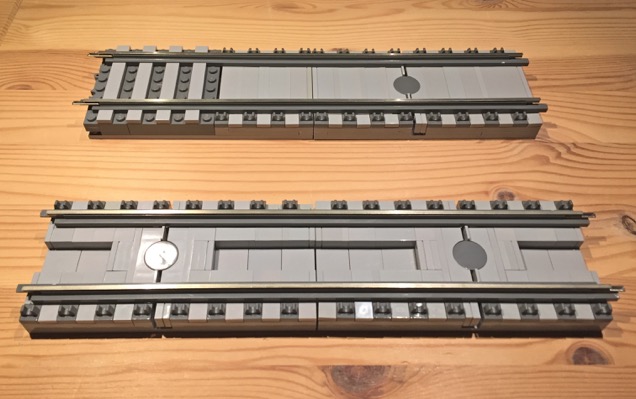

After quite a long wait, I have finally received my much anticipated delivery of ME Models metal track elements.

It appears that the wait has been worth it. Initial exploration with assembling some track sections has put to rest any anxieties of adopting a novel, yet unconventional method of metalizing plastic track. Some observations:

1) The clutch power is much improved over previous ME track. The tendency for ballasted track sections to "explode" with any subtle twisting forces, resulted in me solvent welding the rails to the ballast plates.

2) Rail joints are smooth and seamless. This is not a surprise given that these are effectively HO/OO rail sections with fishplates. This will lead to very smooth running characteristics and superb electrical performance.

3) Nickel silver rail will resist corrosion and improve electrical performance.

4) Separate rail sections will broaden the opportunity to "scratch build" a wider variety of track. I've posted some track sections built to represent precast concrete rail-beds common with many high speed railway lines.

5) Flange way clearance is better without flanges running on the rail base.

My only criticism is the possibility of creating uneven rail height during assembly. My initial tendency when assembling a rail section was to apply force on top of the rail head to secure it to the tie-plates. This would sometimes result in pushing the metal rail insert further into its groove resulting in uneven rail height. I now have to be conscious to apply force to the rail base flange rather than the rail head.

Overall, I say its a big win for us Lego train fans. The only remaining piece of the puzzle is motors with metal wheels!